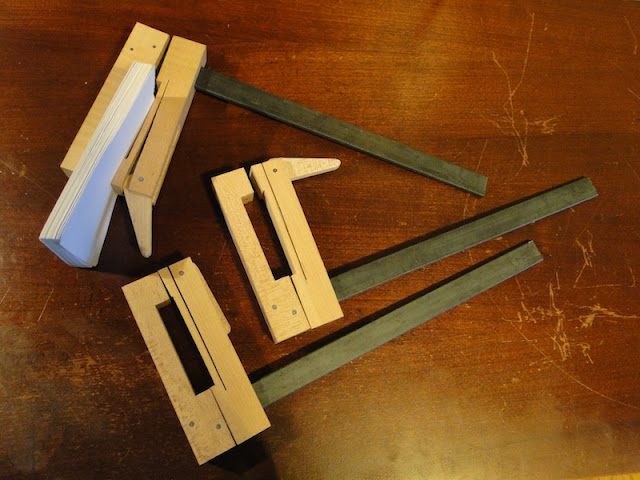

I saw photo's of these in the Stewart Mac catalog and thought I'd make a pair. They are made from 2x4's that were planed square and glued together. The larger has a 5 inch radius for acoustics and the smaller a 3 3/4 radius for electrics and smaller bodied instruments. A spindle sander made the recesses from the squared block and a band saw cut the profiles. There is cork in the recesses for padding.

They seem stable and should make nice rests for routine maintenance like string changing.

These are a series of articles detailing projects that I've built. Click on the Blog Archive arrows to expand the months and see more articles that posted here...

Tuesday, January 31, 2012

Hide Glue

Hide glue is probably one of the best glues available. It was "replaced" years ago by modern glues because of their ease of use and ability to withstand water. Hide glue has several distinct advantages to it. It is extremely strong, it is very hard when dry (it transmits sound vibrations without dampening them), it can be released with heat and water (you can make repairs easily) and joints secured with it have little "creep" to them (they don't move while gluing up). Here is how I mix up a pot of glue.

This is what the glue crystals look like when dry.

I mix one part dry glue with two parts water.

After about an hour the crystals have absorbed the water and they look like "fish eggs."

Next the glue slurry goes into the "glue pot" where it is heated between 140 and 150 degrees.

After about an hour in the pot it looks like this, a clear amber liquid.

Leave sit over night and it will be a clear solid, ready for reheating and use for several weeks. The glue sets very quickly so you have to either work fast or heat the pieces to be glued to increase the glue's open time. Great stuff!

This is what the glue crystals look like when dry.

I mix one part dry glue with two parts water.

After about an hour the crystals have absorbed the water and they look like "fish eggs."

Next the glue slurry goes into the "glue pot" where it is heated between 140 and 150 degrees.

After about an hour in the pot it looks like this, a clear amber liquid.

Leave sit over night and it will be a clear solid, ready for reheating and use for several weeks. The glue sets very quickly so you have to either work fast or heat the pieces to be glued to increase the glue's open time. Great stuff!

Saturday, January 28, 2012

Ukulele Build Part 16 Final

The bridges were glued to the tops using the cam clamps that were detailed earlier in this series of posts. I used a template to find the exact location of the saddle and then marked the perimeter of the bridge with low tack masking tape. This not only showed exactly where the bridge went but it also protected the top from excess hide glue.

The bone nuts were finished by filing the slots for the strings into them and the action of the ukes were set to the specifications in the instruction manual. The fret boards and bridges got a coat of bore oil and the saddles were glued in place with white glue. I made the mistake of stringing the first uke like a guitar (high end smallest string to low end largest string). After consulting the directions I restrung the correct way to G-C-E-A and now they are ready for use. The Grover tuners are much better than the through the head piece friction tuners that came with the kit and I'd recommend getting a set should you choose to build a uke.

I hope that you've enjoyed following along with the build. Now I've got to figure out how to play these...

I hope that you've enjoyed following along with the build. Now I've got to figure out how to play these...

Saturday, January 21, 2012

Ukulele Build Part 15

I decided to finish the uskes before gluing on the finger board or saddle. This made one less thing to mask off and made sanding the finish easier because there was nothing mounted on the uke to get in the way. I masked off the neck as well as the spot on the body where the saddle will be glued on. The ukes were mounted on pieces of doweling ("uke on a stick") to make for easier spraying of the lacquer finish. I decided to try two different finish styles. The uke made from the kit was sanded out to 600 grit wet/dry then 1000 grit wet.dry and then buffed with 0000 steel wool. This left a very soft matt finish that feels really smooth to the touch (great for necks). The scratch built was finished in the same was as the "perfect guitar finish post" describes and is a deep, high gloss. Here are photos of the ukes.

|

| "Steel wool finish Uke on a Stick" |

|

| High gloss finish (the dull spot is where the saddle goes) |

|

| High gloss back with steel wool on the back of the neck |

Tuesday, January 17, 2012

Ukulele Build Part 14

These are some home made cam clamps that will be used to hold the saddle in place for gluing. They needed to have a fairly long throat to them so that they can reach through the sound hole to where be able to hold where the saddle goes. The also needed to have sufficient clearance built into the fixed lowermost jaw so that it can clear the internal sound board bracing. The principle is that when the cam is rotated outward, it causes the movable jaw to bind on the rail and compress the workpiece. The are made from hard maple and plans can be found on the internet.

Binary Clock

Here is a cool project that keeps surprisingly good time. I had wanted to build a binary clock using a PIC F84 microprocessor. A binary clock is one that counts up using the binary counting system of 1's and 0's. In this case the column of lights furthest to the right is the 1's column, followed by the 2's, 4's, 8's, 16's and 32's columns. Using this system 100110 is 32+4+2=38.

The problem with this project was that although I could get the clock to work, I had a miserable time getting the clock to keep accurate time and also be able to display the time using LEDs. If I had a seperate time keeper, the project would have been a breeze but using PIC Basic as the programming language made it hard to be able to tell to the microsecond how long various arguments would take to execute. I gave up a few years ago but revisited this project just about a year and a half ago. This time I came at the problem from the angle of using Assembly Language as the programming language. This took all the timing variables out because I knew the frequency of my crystal and also knew how long each operation would take. After some experimentation on a bread board I had a stable and well functioning circuit. When I soldered up the project, the timing changed and it took several weeks of bench-top experimentation to get the clock working to be accurate to within a second or two per week.

The buttons are for suspending the timer and setting the minutes and hours. It uses a twenty four hour timing period and the LEDs are muiltplexed in sequence because the PIC F84 has only 12 output pins and I need to drive 17 LEDs. The circuit strobes the hours LEDs, then the minutes LEDs and lastly the seconds LEDs. This happens so quickly that there is no blinking or flickering, although there is occasionally a little ghosting in non lit LEDs that can be seen in a very dark room. The power supply is a 9V DC wall transformer and the case is an Altoid tin because every electronics project is cooler if you can fit it in an Altoid tin...

The time is 8:28 and 53 seconds

The problem with this project was that although I could get the clock to work, I had a miserable time getting the clock to keep accurate time and also be able to display the time using LEDs. If I had a seperate time keeper, the project would have been a breeze but using PIC Basic as the programming language made it hard to be able to tell to the microsecond how long various arguments would take to execute. I gave up a few years ago but revisited this project just about a year and a half ago. This time I came at the problem from the angle of using Assembly Language as the programming language. This took all the timing variables out because I knew the frequency of my crystal and also knew how long each operation would take. After some experimentation on a bread board I had a stable and well functioning circuit. When I soldered up the project, the timing changed and it took several weeks of bench-top experimentation to get the clock working to be accurate to within a second or two per week.

The buttons are for suspending the timer and setting the minutes and hours. It uses a twenty four hour timing period and the LEDs are muiltplexed in sequence because the PIC F84 has only 12 output pins and I need to drive 17 LEDs. The circuit strobes the hours LEDs, then the minutes LEDs and lastly the seconds LEDs. This happens so quickly that there is no blinking or flickering, although there is occasionally a little ghosting in non lit LEDs that can be seen in a very dark room. The power supply is a 9V DC wall transformer and the case is an Altoid tin because every electronics project is cooler if you can fit it in an Altoid tin...

The time is 8:28 and 53 seconds

Pinewood Derby Matt Kenseth

Here is a pinewood derby car from several years ago that my son and I built. The decals are made on an ink jet printer and coated in clear acrylic. The shape of the car, sanding and painting were all done by my son when he was in the fifth grade at that time. The car is a lot easier to build than it looks and that is beauty of custom made decals because they allow you the ability to make just about anything you like with a minimum of effort. If you look closely you can see the "battle scars" on the rear spoiler from a fifth grader racing this car...

Pinewood Derby Batmobile

Here is a pinewood derby car from a couple of years ago. It is a reproduction of the Batmobile from the 1960's Batman TV series that many of us know and love. I found plans for a paper model of the car online and resized them to fit a standard size pinewood derby car. The car's body is built up from many pieces of basswood. For example the rear fins, front cowling, arch between the bubble windows, front fins and doors are all glued onto the pine body. This made the car end up just about at 5 oz because basswood is denser than pine. The bubble windows are made from clear plastic and are held in place by super glue. The interior details are decals except for the fire extinguisher between the seats which is made from dowling. The orange pin stripes and exterior markings are also decals, the siren is paper and the wings on the sides of the siren are brass The paint job is black lacquer with a clear coat covering.

Subscribe to:

Comments (Atom)